professional only brand

professional only brand

Best Sellers

Gel Products

Essentials & Accessories

Staleks

Behind the Scenes: Exploring the Manufacturing of Gel Polish Brands

March 21, 2024 2 min read

In the world of nail beauty, gel polish stands out for its durability, vibrant colors, and flawless finish. But have you ever wondered what goes into creating these little bottles of wonder that transform nails into works of art? Today, we're taking you behind the scenes to explore the meticulous manufacturing process of top gel polish brands, shedding light on the innovation, quality control, and commitment to safety that set industry leaders like Miss Dolla apart.

Rigorous Research and Development

The journey of a gel polish begins in the research and development labs, where chemists and nail care experts collaborate to create formulas that are not only long-lasting and chip-resistant but also kind to the nail. At Miss Dolla, we pride ourselves on our investment in R&D, constantly exploring new pigments, formulations, and technologies to improve our products. Our goal is to deliver gel polishes that set trends while ensuring nail health.

Selection of Premium Ingredients

Quality gel polish requires quality ingredients. Top brands scrutinize their materials meticulously, sourcing only the best pigments, resins, and photoinitiators. Miss Dolla takes this a step further by ensuring our ingredients are not just premium but also safe and eco-friendly, aligning with our commitment to cruelty-free beauty and sustainability.

State-of-the-Art Manufacturing

The production of gel polish is a high-tech process that demands precision and cleanliness. In facilities equipped with the latest manufacturing technology, batches are mixed under strict conditions to ensure consistency and purity. Miss Dolla's manufacturing process includes rigorous testing at every stage, from initial mixing to final bottling, ensuring that every product meets our exacting standards for quality and performance.

Comprehensive Quality Control

Quality control is paramount in the production of gel polish. Each batch undergoes several tests, including viscosity, cure time, and color accuracy, to ensure that the final product performs as expected. Miss Dolla implements an extensive QC procedure that not only meets but exceeds industry standards, guaranteeing that our gel polishes are of the highest quality before they reach salons and consumers.

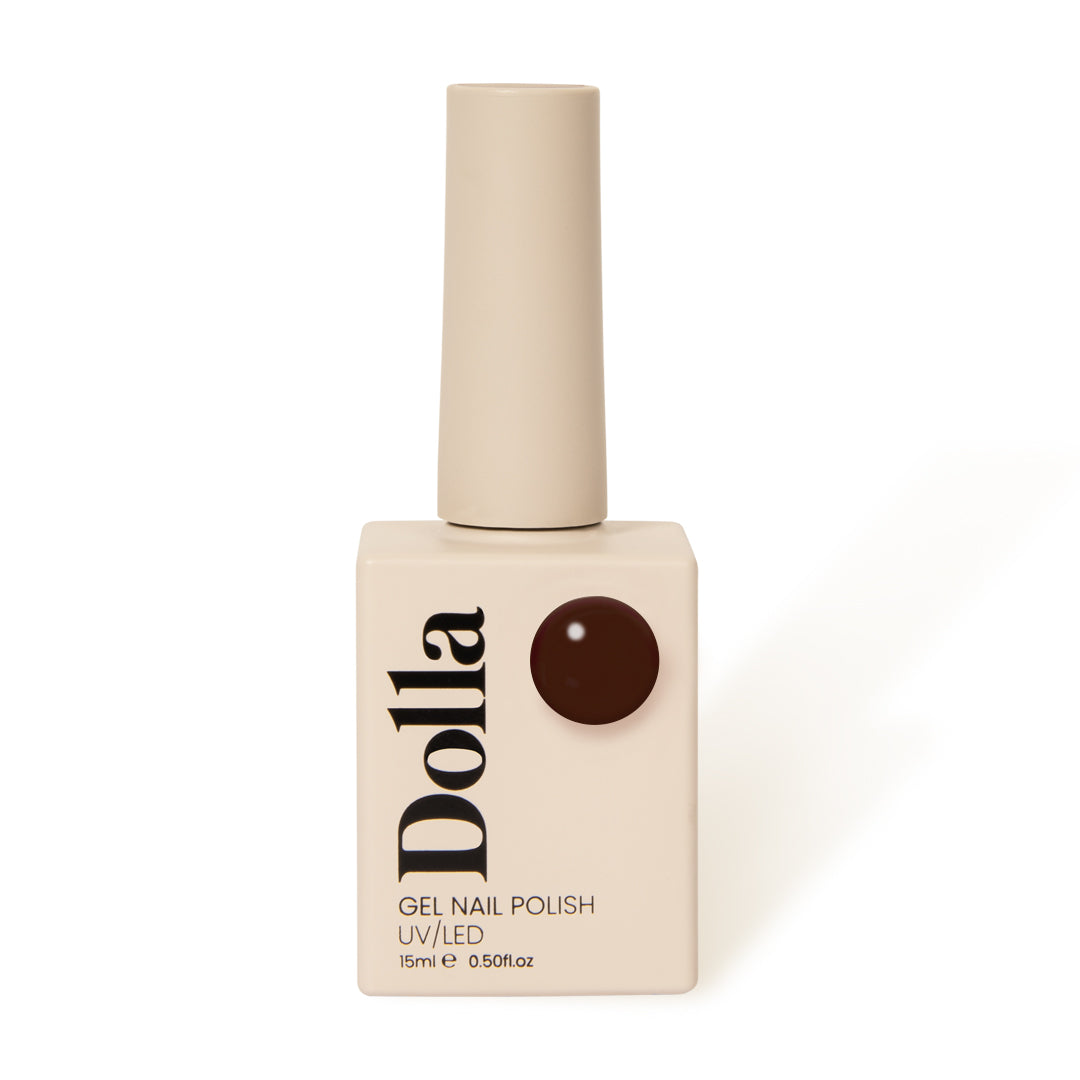

Packaging and Branding

The final step in the manufacturing process is packaging, where the gel polish is filled into bottles and branded. Miss Dolla's distinctive packaging is designed to be both functional and appealing, ensuring ease of use for nail technicians while also standing out on the salon shelf. Our branding reflects our dedication to quality, innovation, and style, making Miss Dolla products a preferred choice for professionals.

Understanding the manufacturing process behind gel polish offers valuable insights into the dedication and innovation that top brands, like Miss Dolla, invest in their products. For nail technicians, choosing gel polishes from companies that prioritize quality, safety, and sustainability is crucial for delivering exceptional manicures that delight clients and uphold industry standards. Explore Miss Dolla's range of premium gel polishes and experience the difference that comes from a commitment to excellence in every

Leave a comment

Comments will be approved before showing up.

Subscribe

Sign up to get the latest on sales, new releases and more …